Overview

With over forty years of experience in designing Current Collector Devices, Mersen continues to strive to develop and deliver the largest product offer with the most advanced technical capabilities of the market, from the most simple CCD to the a solution integrating Smart and Digital solutions to enable you to pilot and anticipate your maintenance at each level of the train life time.

Current Collector Devices are used by Metro, catenary less tramway and electric buses. They are a critical components as they are collecting the energy from the third rail to energize the Electrical Multiple Unit at high speed all along the track.

Benefits

Uses of Current Collector Devices

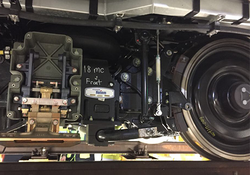

Mersen Current Collector Device’s are designed to be very compact and easy to be installed on the bogie or the frame of the vehicle. They are mostly customized to the bogie space frame while the mechanism is using a proven solution since almost half a century.

They must be reliable and offer low maintenance cost and adapted solutions including innovative and connected functions.

To guarantee this efficiency, Mersen is testing them internally and with external partners.

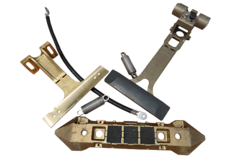

Spare part kits

Mersen will supply you all Spare parts kits to guarantee the reliability and increase the life time of your current collector devices.

- cables,

- fuses,

- replacement shoes and arms,

- Hardware and

- all necessary components

Training and assistance

Mersen Design team is available to support your design and maintenance team’s especially for the smart and connected functions.

Mersen Service team can train your Maintenance team to make the setting and the maintenance of your installations all around the world.

Show less

Capabilities

Largest range of the market, Reliability, Low maintenance cost, Innovation

The comprehensive range of CCD for Metro is designed for all kind of configurations:

- Regular steel wheel Metro

- Pneumatic wheel Metro,

- Monorail

- Driverless metro applications

- Catenary less tramway

- Electrical buses

They can operate under 750VDC and 1.500VDC with sliding (dynamic) or static (from the ground or from the roof) collection.

All technologies can be customized to your technical environments and available space on your bogie or frame.

The sliding shoes can be retracted manually or using a pneumatic system also the CCD can be fixed on a beam and integrate a DC fuse protection and smart and Digital connected function.

Design Guide

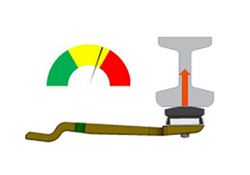

Patented Pressure controller system (smart and connected function)

Mersen innovate in offering the possibility to equip the CCD’s with a sensor to measure the contact force of the CCD against the third rail all along the track with possibility to record this measurement. Too much pressure force and the mileage of the shoe will be shorten, too less and there will be a risk of losing the contact and generate arcing.

Broken arm detection device (smart and connected function)

In case the CCD’s meet an obstacle on the track , the weak link of the CCD will sacrifice itself and brake saving the CCD Frame but with of a broken arm, the motor car and the trailers will run under failed mode (3 CCD instead of 4).

Mersen have innovated by proposing a combination of mechanical and electrical systems which detect instantaneously a broken arm and relay the information to the TMS and the driver.

Temperature measurement (smart and connected function)

In case of a broken arm, the motor car and the trailers will run under failed mode (3 CCD collecting energy instead of 4). Mersen have developed a system which measure live the temperature of the CCD and bring this information to the TMS.

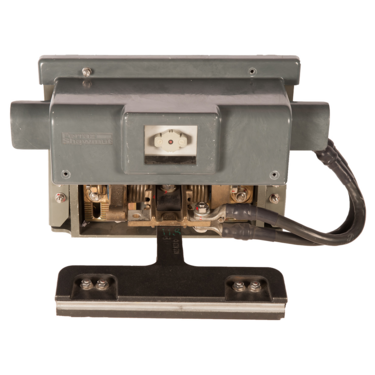

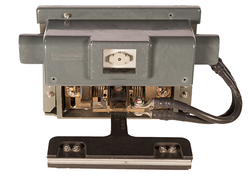

Integrated or separated fuse box

The fuse protection needs to be as close as possible from the source of energy, this is why Mersen advice to integrate the fuse protection in the CCD. The fuse box can be located in all positions (on top, at the bottom, on the sides and underneath of the CCD).

Sometimes, the available space is not sufficient; in this case Mersen can separate the fuse box from the CCD connected with dedicated railway cables.

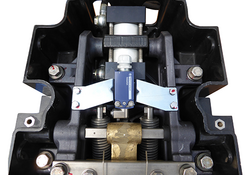

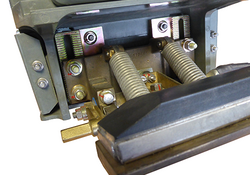

Manual or Pneumatic retraction

The manual retraction is the most simple and cost effective retraction system using a retracting lever to retract each CCD of the train.

The pneumatic retraction is using an air cylinder to retract all the CCD of the train at the same time from a simple operation.

Both systems are equipped with a locking system to secure the retracted position. Air cylinder need 6 Bars of pressure to retract the arm.

Retraction position indication

To inform the driver of the retracted position of the CCD, Mersen can integrate a micro-switch to relay the information of the position. This micro switch is compatible with all traction battery voltage supply (12, 24, 48 and 110VDC).

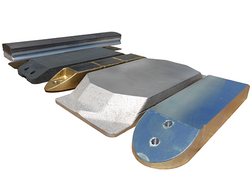

Shoe material

Mersen can propose different Shoe materials - Copper; Graphite; Cast iron; Steel; Cupro Alu adapted to your third rail.

Once they are worn, it is very easy to change them for new ones supplied by Mersen.

Those shoes can show a wearing limit to inform when they need to be changed.

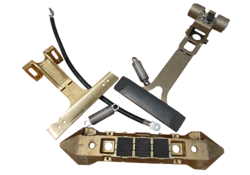

Weak link

To secure your CCD in case of shock or meeting an obstacle on the track, your CCD can be equipped with a weak link.

When the CCD hits an obstacle, the arm will break at the weak link section and leave in safe condition the CCD device.

Adjusting rack

The CCD are equipped with an adjusting rack in order to adjust the shoe in vertical position in relation to the wheel overhauling and reprofiling wheel. This adjusting rack can allow 40mm adjustment (pitch = 4mm).

On a beam

The CCD can be installed on a beam to adjust the position of the CCD from the bogie vs the position of the 3rd rail.

Work shop plug

The CCD can be equipped with a work shop plug in case you need to power the train when the third rail is not available (in the work shop for auxiliary circuits).

Painting of Steel covers

Mersen can paint the covers or mass taint the isolated plastic frame of your CCD to the colour specified by you, for purely cosmetic reasons.

Identification

Each CCD is identified individually with rank number on its name plate. Mersen can also add a bar code or QR code.

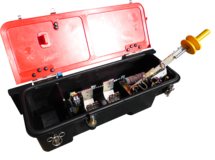

Tooling

Beside the spare parts, Mersen can supply the necessary tooling to set perfectly your CCD to the technical requirements of your grid and optimize their use.

High, Low and nominal position have to be set, also, the tool include a pressure measurement system to check the pressure of the CCD on the 3rd rail. This tool is mandatory to succeed in the great overhaul and guarantee a reliable service and longer life time of your CCD fleet.

LCC; RAMS; Type tests

Mersen team provide type test and different studies (Life Cycle Cost, RAMS, FMEA, Eco Design and recyclability, etc…) to secure the reliability of your CCD solution and its conformity to standards and legislations.

Documents & Resources

CCD for Standard bogie

CCD for Rubber wheels

CCD for Monorail/Skytrain

CCD for Tramway Wireless

Show less

CCD range

- Compact and manual retraction w/o Fuse box

- Compact and manual retraction including Fuse box

- Compact and Pneumatic retraction w/o fuse box

- Compact and Pneumatic retraction including fuse box

- Fixed on beam

- Positive fuse box included

- Positive Track with separate Fuse box

- Negative (sliding on the track)

- Negative (sliding on a lateral rail)

- Dual lateral contact

- Monorail

- Static Contact (tramway and electrical buses) ground and roof

- Sliding Contact (tramway)

Completed Projects

- Steel wheel Metro (Paris, Singapore, Tokyo, New York, Buenos Aires, Mexico, Madrid, Bangalore, Beijing, Alger, Cairo, Istanbul, …)

- Pneumatic wheel Metro (Paris, Montreal, Santiago of Chile),

- Monorail (Las Vegas)

- Driverless metro applications (Toulouse, Lille, Roissy Airport, Orly Airport, Turino, Seoul airport, Taipei, Chicago, …)

- Catenary less tramway (Luxemburg, Nice, Saragossa)

- Electrical buses (under test)