Optimized and Compact Design

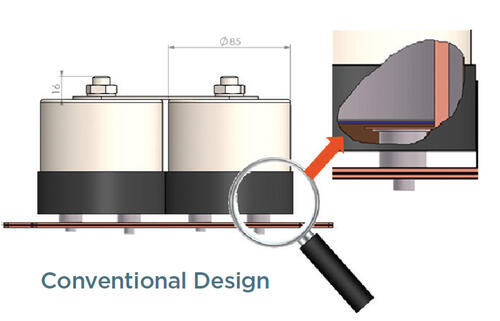

Mersen Fischerlink 2.0 is an optimally designed and assembled capacitor and bus bar sub assembly. Traditionally capacitors are connected to bus bars by screw or solder connections which may cause increased inductance in the sub-assembly. Mersen Fischerlink 2.0 uses laser welding to connect capacitor terminals to bus bars, thus improving the overall performance of the assembly and reducing the footprint.

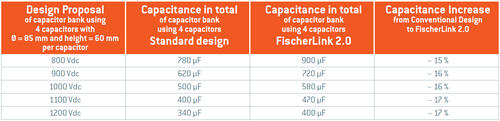

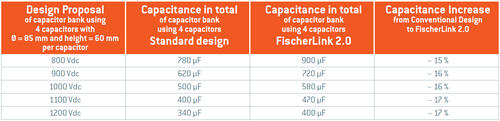

Laser welding the connections has several advantages compared to traditional screw or solder mounting methods. Laser welding reduces the inductance and increases capacitance. Additionally the capacitance per volume can be increased up to 20%. Since the assembly is done by Mersen, all parts are 100% tested before delivery providing customer an additional degree of peace of mind. The sub-assembly of capacitor and bus bar rolled into one single part number offers additional savings in administrative costs.

Design Performance Comparison Example

Resources